How Tata is Building a Semiconductor Chip Empire in Dholera (2024–2027 Timeline)

Table of Contents

- Why Dholera Matters in India’s Semiconductor Story

- Tata Semiconductor Project Timeline (2024–2027)

- January 2024: Project Announcement

- February 29, 2024: Government Approvals

- March 13, 2024: Virtual Bhumi Pujan & Foundation Laying

- August 3, 2024: Physical Bhumi Pujan & Construction Begins (Assam)

- 2024–2025: Infrastructure & Civil Work

- Mid-2025 to Late-2025: Assam OSAT First Phase

- 2025–2026: Equipment Installation & Testing (Dholera)

- Late 2026: Initial Commercial Production

- Late 2027: Stabilisation & Ecosystem Expansion

- Technology, Capacity, and Investment Snapshot

- Beyond Chips: Dholera’s Growing Industrial Ecosystem

- Conclusion

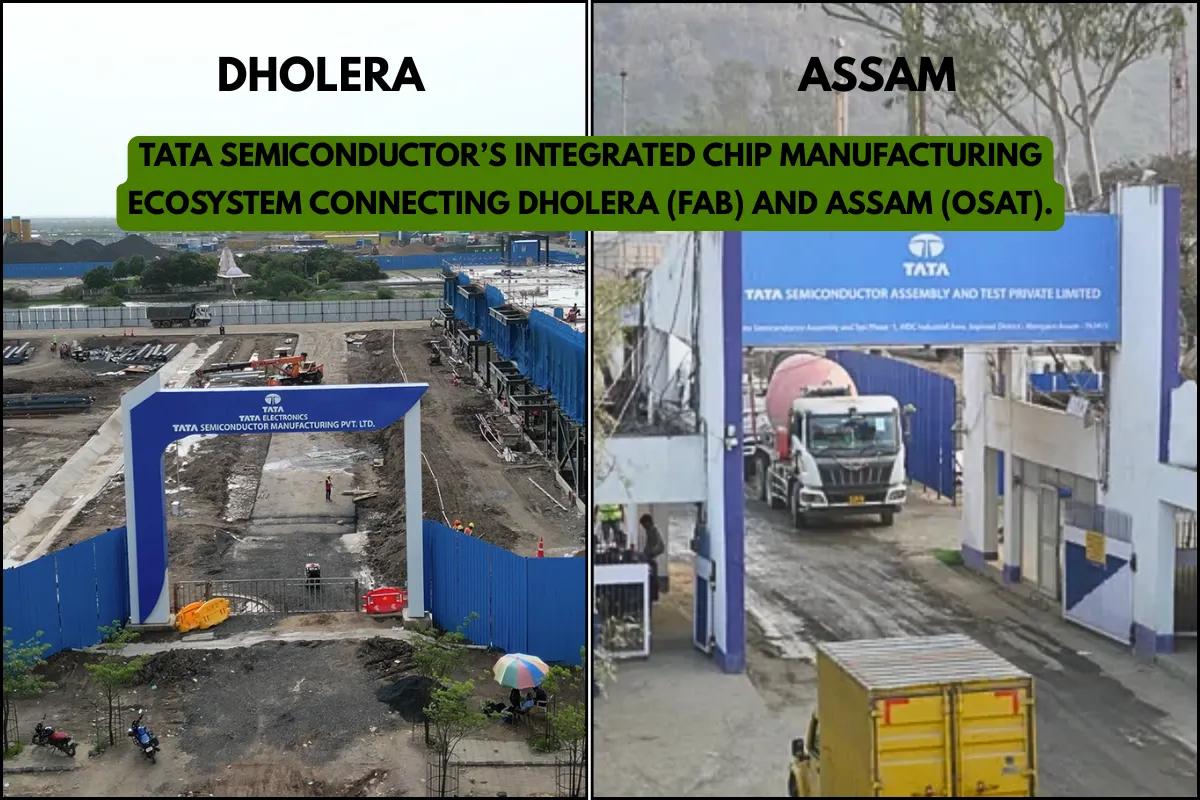

The semiconductor industry in India is undergoing a transformative shift, and the Tata Group is at the forefront of this revolution. With a combined investment of ₹1.18 lakh crore for its projects in Dholera Smart City, Gujarat, and an OSAT (assembly & test) facility in Assam, Tata is set to create a robust semiconductor ecosystem in India while positioning the country as a global hub for chip manufacturing.

This blog explores Tata’s Dholera semiconductor project timeline, development milestones, fabrication capacity, and future expansion potential, highlighting why Dholera SIR investment and smart city infrastructure make this region a magnet for industrial growth.

Why Dholera Matters in India’s Semiconductor Story

The rise of Tata Semiconductor goes beyond just chip manufacturing. Dholera, as a Greenfield Smart City, is strategically located with airport and port connectivity, integrated industrial zones, and renewable energy initiatives such as the Dholera Solar Park.

Alongside Tata Semiconductor, multiple industries and EV manufacturing units, logistics hubs, and warehousing sectors are establishing themselves here, creating a multi-sector ecosystem. This convergence of infrastructure and industry positions Dholera as one of the best cities to invest in India for long-term growth.

Tata Semiconductor Project Timeline (2024–2027)

January 2024: Project Announcement

At the Vibrant Gujarat Global Summit 2024, the Tata Group announced plans to build India’s first large-scale semiconductor fabrication plant in Dholera, in partnership with Taiwan’s Powerchip Semiconductor Manufacturing Corporation (PSMC).

The integrated project also included an OSAT facility in Jagiroad, Assam, completing a full semiconductor manufacturing value chain within India.

February 29, 2024: Government Approvals

The Union Cabinet approved Tata Electronics’ semiconductor projects under the India Semiconductor Mission:

- ₹91,000 crore for the Dholera fab

- ₹27,000 crore for the Assam OSAT facility

This marked one of the largest single investments in semiconductor manufacturing in India.

March 13, 2024: Virtual Bhumi Pujan & Foundation Laying

Prime Minister Narendra Modi virtually performed the Bhumi Pujan and laid the foundation stones for the Dholera fab and Assam OSAT. The combined investment of ₹1.18–1.26 lakh crore made this one of India’s largest industrial initiatives under the Dholera Smart City project.

August 3, 2024: Physical Bhumi Pujan & Construction Begins (Assam)

The on-ground Bhumi Pujan for Assam OSAT marked the start of civil construction.

Key Highlights:

- Technologies: Wire Bond, Flip Chip, Integrated Systems Packaging (ISP)

- Target Output: ~48 million chips per day

Construction began immediately after the ceremony, alongside local employment and skill development initiatives.

2024–2025: Infrastructure & Civil Work

Dholera Fab

- Land preparation, clean rooms, utilities, and supporting infrastructure

- Integration with Dholera Industrial Area, Dholera Solar Park, and smart city water management systems

Assam OSAT

- Structural and foundation work progressed

- Connectivity boosted via Ahmedabad–Dholera Expressway and proximity to Dholera International Airport

Mid-2025 to Late-2025: Assam OSAT First Phase

The first operational phase of Assam OSAT is expected by mid-to-late 2025, beginning chip assembly and testing to serve India’s growing electronics manufacturing sector.

2025–2026: Equipment Installation & Testing (Dholera)

During this period, advanced wafer fabrication equipment was installed, clean-room systems were calibrated, and trial production began—laying the foundation for Dholera to become a leading semiconductor fab in India.

Late 2026: Initial Commercial Production

The Dholera fab is expected to produce its first commercial chips by late 2026, focusing on:

- Power management ICs

- Microcontrollers

- Automotive and logic chips

The Assam OSAT facility is expected to scale in parallel for both domestic and international markets.

Late 2027: Stabilisation & Ecosystem Expansion

By 2027, production at Dholera is expected to stabilise and scale further. Tata Electronics has indicated long-term expansion potential, including possible collaboration with Intel Semiconductor Manufacturing India, subject to approvals and market conditions.

Technology, Capacity, and Investment Snapshot

- Manufacturing Nodes: 28nm, 40nm, 55nm, 90nm, 110nm

- Dholera Fab Capacity: ~50,000 wafers per month

- Assam OSAT Capacity: ~48 million chips per day

- Total Investment: ~₹1.18 lakh crore

- Employment Impact: ~50,000 direct and indirect jobs

Beyond Chips: Dholera’s Growing Industrial Ecosystem

Tata Semiconductor acts as the industrial anchor, but the region is also seeing growth in

- Renewable energy projects

- Automotive & EV manufacturing

- Logistics and warehousing

- Smart city infrastructure

With the Ahmedabad–Dholera Expressway, port connectivity, Dholera Solar Park, Dholera International Airport, and EV charging infrastructure, Dholera is shaping up as a future industrial hub of India.

Conclusion

manufacturing. Supported by government incentives, strategic global technology partnerships, and world-class infrastructure in Dholera Smart City, India, the project is poised to build a resilient semiconductor ecosystem, attract multiple industries, and transform Dholera into a multi-sector industrial hub for the future.

Beyond semiconductors, the initiative is expected to catalyse growth in related sectors such as automotive and EV manufacturing, logistics and warehousing, renewable energy, and smart city infrastructure. The presence of large-scale infrastructure projects like the Ahmedabad–Dholera Expressway, Dholera International Airport, and Dholera Solar Park further enhances the region’s attractiveness for investors and businesses.